For 24-hour Emergency Service, call: (315) 703-9708

PowerLine™ is a new generation of line shaft hoist, re-engineered to reduce size, weight and cost. PowerLine hoists offer a wide range of speeds and capacities, making them versatile performers. These hoists virtually eliminate side loading on the building structure caused by the rigging and can be excellent choices for retrofits in older buildings.

Speed: Up to 240 fpm (1.2 m/s)

Travel: 60 ft (18.3 m)

Gross Cap.: Up to 2500 lb (1,135 kg)

PowerLine's compact size makes it ideal for smaller spaces and renovations. Among its many uses are electric sets, scenery and curtains, and front-of-house lighting sets.

PowerLine works with the entire range of Clancy automation consoles or push button controls. It can also interface with any modern control system.

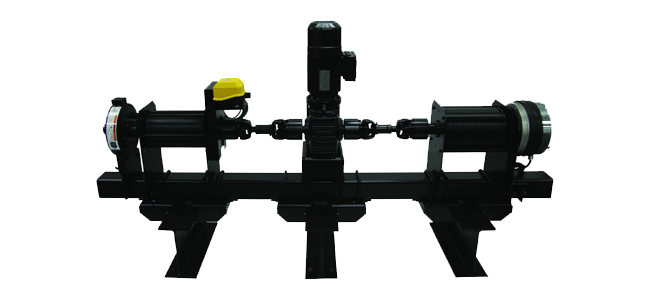

Base configuration has gear motor with integral brake on one end and centrifugal load brake on other end.

| Description | Speed/Gross Capacity | ||

|---|---|---|---|

| Fixed Speed | 20 fpm / 1000 lb (0.1 m/s / 454 kg) 20 fpm / 1250 lb (0.1 m/s / 567 kg) 20 fpm / 1600 lb (0.1 m/s / 726 kg) 20 fpm / 2150 lb (0.1 m/s / 975 kg) 20 fpm / 2500 lb (0.1 m/s / 1134 kg) |

||

| Variable Speed | 0 – 110 fpm / 1300 lb (0 – 0.56 m/s / 590 kg) 0 – 140 fpm / 1950 lb (0 – 0.71 m/s / 885 kg) 0 – 240 fpm / 2300 lb (0 – 1.2 m/s / 1043 kg) |

||

| Options | Lift Line | Drum Dia. | Max Load/Line |

| Option 1 | 1/4" (6.35 mm) | 7-1/2" (190 mm) | 750 lb (341 kg) |

| Option 2 | 3/16" (4.8 mm) | 5-1/2" (140 mm) | 500 lb (227 kg) |

PowerLine is available in several, standard configurations and can also be customized to your needs. Contact your Wenger | J.R. Clancy representative to discuss optimal configurations or custom solutions.